Key Slot Cutting Machine

Introduction: How to Broach a Keyway

- Car Key Cutting Machine

- Key Slot Cutting Machine Tools

- Key Slot Cutting Machine Tool

- Manual Key Cutting Machine

- Best Key Cutting Machine

Keys are an important part of mechanisms. They provide a solid and reliable interface between shafts and a wide variety of other objects including pulleys (as in my case), sprockets, levers and gears. There are a variety of different types of keys, but the simplest and most common is the straight key.

For this project, I'll be broaching keyways in some pulleys that I'm in the process of machining (still need to finish up the OD). The material is 6061 aluminum, it's 3/8' thick with a ø3/8' hole and I'll be broaching a 3/32' keyway.

Step 1: Tools and Materials

Tools:

Broach Kit, including a broach, shims (as needed) and the appropriate bushing.

Arbor or Hydraulic Pres

Materials:

Cutting Oil, my favorite is Tap Magic

Step 2: Setting Up

This is a small broach in soft material, so I can easily use the 3 ton arbor press. If you're broaching a tougher material and/or a larger broach, you'll need a hydraulic press, as large broaches can require thousands of pound of pressure to cut. Also, larger broaches are much longer and often do not fit in an arbor press.

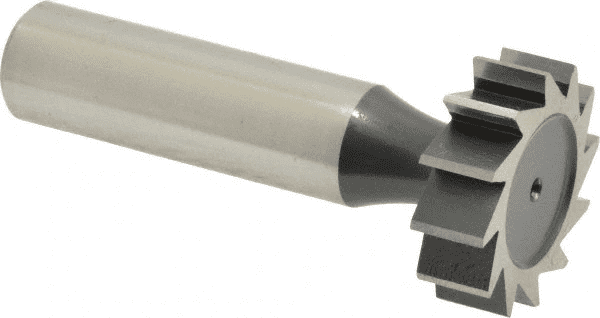

Parallel keys are the simplest, and involve a slot that goes all the way through at least the part with the shortest axial mating length (i.e. The gear or the pulley. Cutting a parallel key is straightforward–just use an endmill and treat it as cutting any other slot. Alternatively, you could use a Keyseat Cutter such as a Woodruff Cutter. In mechanical engineering, a key is a machine element used to connect a rotating machine element to a shaft. The key prevents relative rotation between the two parts and may enable torque transmission. For a key to function, the shaft and rotating machine element must have a keyway and a keyseat, which is a slot and pocket in which the key fits. T-SLOT CUTTERS with Parallel Shank or Taper Shank have Side & Face cutting edges, which feed into a work piece to produce a 'T' slot conforming to IS:2668-2004. Available in Straight Teeth, Staggered teeth or Roughing type. Find here Key Cutting Machines, Electronic Key Cutting Machine manufacturers, suppliers & exporters in India. Get contact details & address of companies manufacturing and supplying Key Cutting Machines, Electronic Key Cutting Machine, Key Cutting Machinery across India. Use these end mills for general purpose keyseat cutting in a wide range of material, including aluminum, iron, and steel. They mill precise notches in rotary shafts to fit machine keys and can also be used for slot milling.

For this setup, I've selected the ø3/8' bushing, and the 3/32' broach. They should fit together well, sliding easily without any slop. Since the keyway is so small, I will not be needing any shims, which are used with larger broaches.

Insert the bushing into the hole you wish to broach. It should drop in easily. Next, rotate the slot to where you wish to cut the key. Liberally lube up the broach with your favorite cutting oil and and insert the broach into the slot in the bushing. The first quarter or so should slid in easily before the teeth engage with the part.

Step 3: Broaching

Align the part with the gap in the press and ensure the broach is straight up and down. Then apply even pressure, ensuring that the part is not tilting or rocking off the arbor press work surface. In aluminum it requires little effort. Be prepared to catch the broach as it reaches the end of its stroke- it may fall out. If the broach remains stuck in the part, use a small punch or piece of stock to press it all the way out. Do not strike the broach, as you can mushroom the end (sometimes imperceptibly) and cause yourself a big headache. Only press a broach.

Step 4: Resetting & Test Fitting

With the broach removed, use a chip brush to remove the swarf from the broach. It's important to clean these chips before broaching another keyway. Failure to do so can result in the broach jamming in the bore.

Now, we can take a key and test fit the freshly broached pulley with a shaft. It's a perfect fit. Often times I purchased shafts that already have the keyway machined in them. They are available from McMaster Carr.

Be the First to Share

Recommendations

Car Key Cutting Machine

Anything Goes Contest

Make it Real Student Design Challenge

Block Code Contest

In this article we will see the basic difference between slot , holes, groove, and keyways.

1. Hole: circular cutout, either through the material or to a blind depth.

Types of Hole :

They are different types of holes that are mentioned below.

1.Simple Hole

2.Counter board

3.counter sunk

4.Tapered

5.counter drilled.

2. Slot or Slotted Holes: an elongated hole. It is stretched in one direction but still has full radii on the ends. A slot is cut into a flat plate or normal to the axis of a cylinder.

Slot Hole Design Consideration :

Slotted holes are widely used in most sorts of mechanical design. Apply mainly in precisely fine-tuning for uncontrollable dimensions beforehand, alignment accuracy, fixation in certain direction meanwhile keeping slipping free in other directions, and so on. Such as tension device of belt pulley, thermal stress protection for slender bar structural parts or long spindle shafts, alignment accuracy in complex dimension chain, a mechanism for enhancing tolerance, and eliminating accumulated error.

In mechanical design, some principles and factors we should take into account include the shape and travel of the slotted holes, the structural strength affected by the holes, and so on. In actual application, they can be classified into the following types: singleton slotted holes, coupled slotted holes.

Slotted Holes Slotted holes can be dimensioned in several different ways.

a. Center points on the longitudinal axis are located and the radii are indicated with a note.

b. Linear measurements indicate the overall size of the slot and the radii are specified.

c. A note indicates the two linear dimensions of the slot and another note specifies the radii.

Choose the most appropriate technique for sizing the slotted hole. The technique used for sizing the slot determines how the slot is located.

Key Slot Cutting Machine Tools

See Also: What is Slotting Machine- Principal parts of Slotter Machine

3. Groove:a groove is a cylindrical slot. Grooves are cut around the OD or ID of a cylinder and do not pass through the axis of the cylinder.

You can simply understand that a slot can be through or blind but a groove is always blind.

In manufacturing or mechanical engineering a groove is a long and narrow indentation built into a material, generally for the purpose of allowing another material or part to move within the groove and be guided by it.

Examples include:

- A canal cut in a hard material, usually metal. This canal can be round, oval or an arc in order to receive another component such as a boss, a tongue or a gasket. It can also be on the circumference of a dowel, a bolt, an axle or on the outside or inside of a tube or pipe etc. This canal may receive a circlip an o-ring or a gasket.

- A depression on the entire circumference of a cast or machined wheel, a pulley or sheave. This depression may receive a cable, a rope or a belt.

- A longitudinal channel formed in a hot rolled rail profile such as a grooved rail. This groove is for the flange on a train wheel.

Key Slot Cutting Machine Tool

4. Keyway:

In mechanical engineering, a key is a machine element used to connect a rotating machine element to a shaft. The key prevents relative rotation between the two parts and may enable torque transmission. For a key to function, the shaft and rotating machine element must have a keyway and a keyseat, which is a slot and pocket in which the key fits. The whole system is called a keyed joint.

Manual Key Cutting Machine

Read More: Types Of Mechanical Keys- Design Of Keys.